Introduction:

In the ever-evolving landscape of

aquaculture, shrimp nurseries are becoming more and more important for survival

of shrimps and getting sufficient return on investment from shrimp or prawn

farming. And so ensuring the optimal conditions for shrimp nurseries is very

important to success.

Adequate aeration plays a crucial role

in creating a thriving environment for shrimp larvae, and among the various

aeration methods available, diffused aeration using aeration tubes stands out

as an innovative solution. This blog delves into the advantages of diffused

aeration, specifically when utilizing AirOxi aeration tubes, shedding light on

how this technology can improve shrimp nursery operations and help increase

shrimp survival rates.

The Importance of Aeration in Shrimp

Nurseries:

Maintaining proper oxygen levels is

critical in shrimp nurseries, where factors such as high stocking densities and

the rapid growth of larvae demand an increased oxygen supply. Inadequate

aeration can lead to stress, slow growth, and increased vulnerability to

diseases. To address these challenges, aquaculturists are turning to diffused

aeration systems, and aeration tubes have emerged as a preferred choice due to

their many benefits over traditional aeration methods.

Understanding Diffused Aeration:

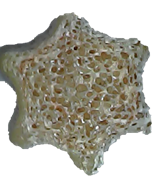

Diffused aeration involves releasing

fine bubbles into the water, creating a large surface area for efficient gas

exchange. Aeration tubes, designed to evenly disperse bubbles throughout the

water column, offer advantages such as increased oxygen transfer efficiency,

reduced energy consumption, and the ability to create a more uniform

environment for shrimp larvae.

The AirOxi Advantage:

Enter AirOxi – a leading brand in

aeration technology. AirOxi aeration tubes are engineered to deliver optimal

performance in aquaculture settings, particularly shrimp nurseries. The unique

design of AirOxi tubes ensures a continuous release of fine bubbles, promoting

efficient oxygen dissolution and water circulation. This not only enhances

oxygen transfer but also helps maintain consistent water parameters crucial for

the well-being of shrimp larvae. Shrimp nurseries require high water movement

as well an AirOxi tubes are designed with the perfect balance of aeration and

water movement.

Benefits of Diffused Aeration with

AirOxi Tubes:

11. Optimal Oxygen Transfer Efficiency:

·

The fine bubbles generated by AirOxi tubes maximize the surface area for

oxygen transfer, ensuring that shrimp larvae receive an ample oxygen supply.

22. Uniform Water Circulation:

·

The even dispersion of bubbles throughout the water column promotes

uniform water circulation, preventing the formation of oxygen-deprived zones

and maintaining a consistent environment for shrimp larvae. The water movement

created by the AirOxi tubes is also important for health of shrimps.

33. Energy Efficiency:

·

Compared to traditional aeration methods like paddle wheel aerators,

diffused aeration using AirOxi tubes consumes 70% less energy, contributing to

cost savings for shrimp farmers.

44. Durability and Longevity:

·

AirOxi aeration tubes are built to withstand the harsh conditions of

aquaculture environments, ensuring long-term durability and reliable

performance.

55. Ease of Installation and Maintenance:

·

The user-friendly design of AirOxi tubes facilitates easy installation

and maintenance, reducing downtime and streamlining nursery operations.

Incorporating Innovation into Shrimp

Farming:

As shrimp farming continues to

evolve, adaption new technologies becomes crucial for success. Diffused

aeration using AirOxi tubes shows this commitment to innovation, offering

shrimp farmers a reliable and efficient solution to improve water quality and

optimize production, as well as reduce cost of production per ton of shrimp.

Conclusion:

In conclusion, the integration of

diffused aeration with AirOxi aeration tubes represents a transformative

approach to shrimp nursery management. By prioritizing optimal oxygen levels,

water circulation, and energy efficiency, this technology contributes

significantly to the overall health and productivity of shrimp larvae. As aqua

farmers endeavours strive for sustainability and efficiency, adopting advanced

aeration solutions like AirOxi becomes not only a choice but a necessity for a thriving

shrimp nursery.

To know more call us at:

+91 – 9652122060

Email: marketing.airoxitube@gmail.com

www.buy.airoxi.com

#envirment #everyone #airoxitube #airoxi

#airoxidiffuser #airoxiproducts #aquarium #aquaculture #fishing #fishingfarm

#shrimp #shrimptank #fishtank #tank #RAS #aeration #aerationsystem #bubble

#post #postoftheday #oxygenation #hatcheries #shrimpfarm #aqualife #blower

#microbubblegenerator #transportationaeration #turbineblower

#submersibleaerator #biofloc #growoutponds #nurseries #oxygenconcentrator

#diffuser